Manufacturer of Wireless Data Collection Systems

Tel (937) 364 1000

Fax (937) 364 2072

Email: sales@psensortech.com

Preditive Sensor Technology

316 N Main St

Lynchburg, Ohio 45142

QUESTIONS? CALL: (937) 364-1000

PREDICTIVE SENSOR TECHNOLOGY, THE QUALITY SOLUTION

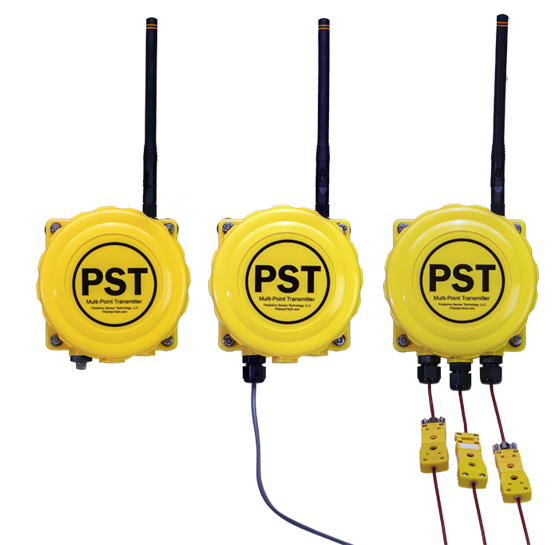

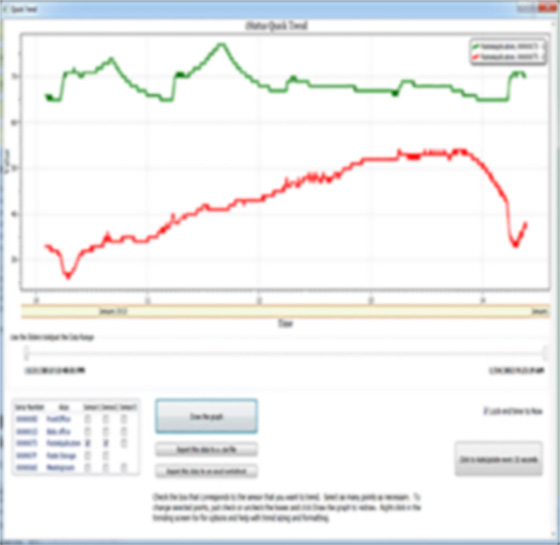

PST is the best solution for quality wireless monitoring products and software.

ENVIRONMENTAL CONDITIONS

Great for measuring temperature, humidity and air qualityVIBRATION SENSORS

Assurance that all of your machinery is working properlyIDENTIFY BOTTLENECKS

Increase throughput of your processes